Water management plans are developed by the operator and approved by the regulator to effectively acquire, utilize and dispose of water used for fracking. Regulations require water applications and permits during all stages of a fracking operation.

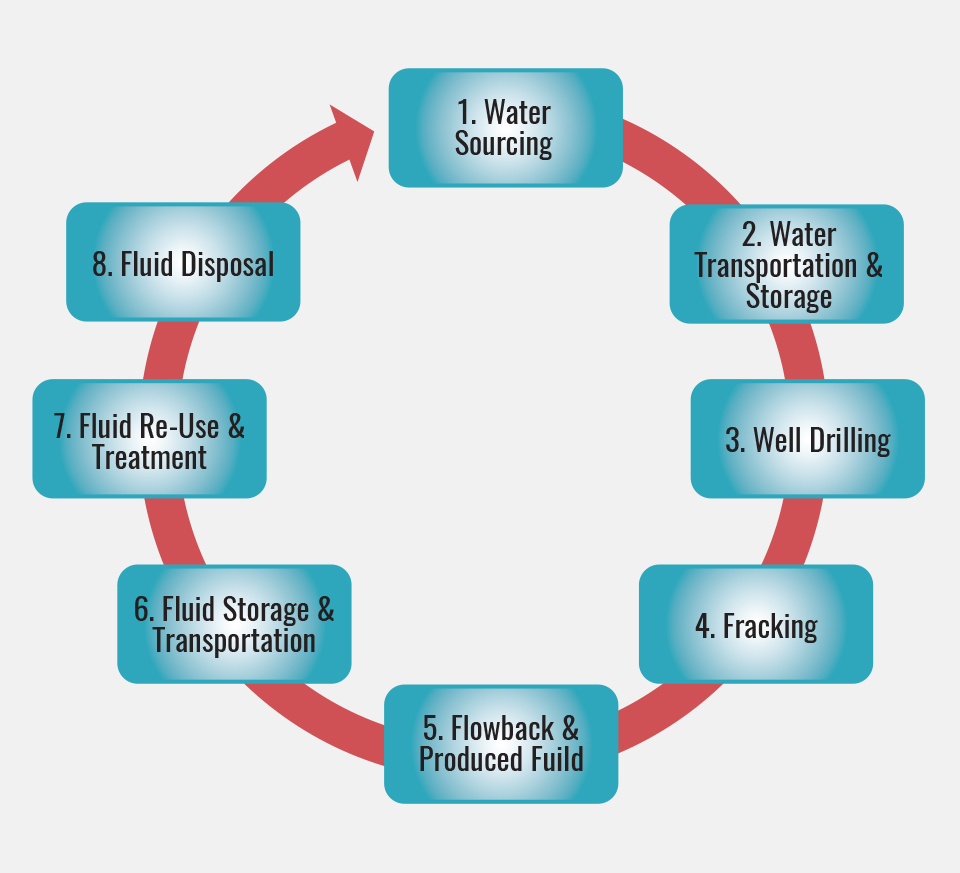

The Fracking Water Management Cycle demonstrates how water is managed during various components of a fracking operation. Industry practices and strict regulations ensure the environment is protected during each component.

Source: Streamflow

1. Water Sourcing for any oil or gas field operation including both drilling and fracking may be obtained from:

- Surface water bodies (rivers, lakes, ponds, collection ponds/ borrow pits)

- Groundwater (shallow and deep, fresh or saline)

- Industry and municipal wastewater

- Re-used or re-cycled flowback and produced water

2. Water Transportation & Storage

Water is transported from its source location to the wellsite by:

- Tanker truck

- Pipelines

Water is stored at the wellsite in:

- Freshwater storage ponds

- Tanks

3. Well Drilling requires water and the amounts needed vary from about 200 to 1,500 m3 per well.

4. Fracking

Frac fluid is mixed in blenders on the wellsite in preparation to be injected down the wellbore. Water volumes range from about 500 to 100,000 cubic meters (m3) of water per well and depend on many factors, including:

- Target rock characteristics (thickness, brittleness, etc.)

- Horizontal well length

- Number of fracturing stages

5. Flowback & Produced Fluid:

- The well bore is flushed out and fluids flow back to the surface.

- Flowback fluids are collected and held temporarily (days to months) at the wellsite, during flowback testing and early production operations.

6. Fluid Storage & Transportation

The storage of flowback and produced fluids is strictly regulated:

- Operators must store these fluids in tanks, c-rings or double-lined pits, depending on the jurisdiction.

- Typically a secondary barrier is required in the event that containment is breached. This secondary containment is designed to be capable of holding all the fluids.

7. Fluid Re-Use & Treatment

Fluids may be treated and then re-used, for other fracking operations:

- There are numerous techniques being developed to treat fluids for both re-use and disposal.

- Most commonly, fluids are passed through a 5 micron filter and treated with a biocide to inhibit bacterial growth.

8. Fluid Disposal

If the fluid can no longer be appropriately stored or re-used for fracking, it must go to a fully approved disposal well or disposal facility:

- The fluid is usually trucked or sent via pipeline to these sites.

- At a disposal facility (well), the waste fluid is pumped deep underground, into a porous formation, using a wellbore reviewed and approved by the regulator.

Water management for fracking operations has evolved rapidly over the last 5 years; a few examples include:

- Specialized water management firms have been established to provide equipment but also important management and logistical skills to manage water safely and responsibly

- The British Columbia Oil and Gas Commission has developed several tools for water management

- Petroleum water management has become a recognized course subject in petroleum programs at university and polytechnic level