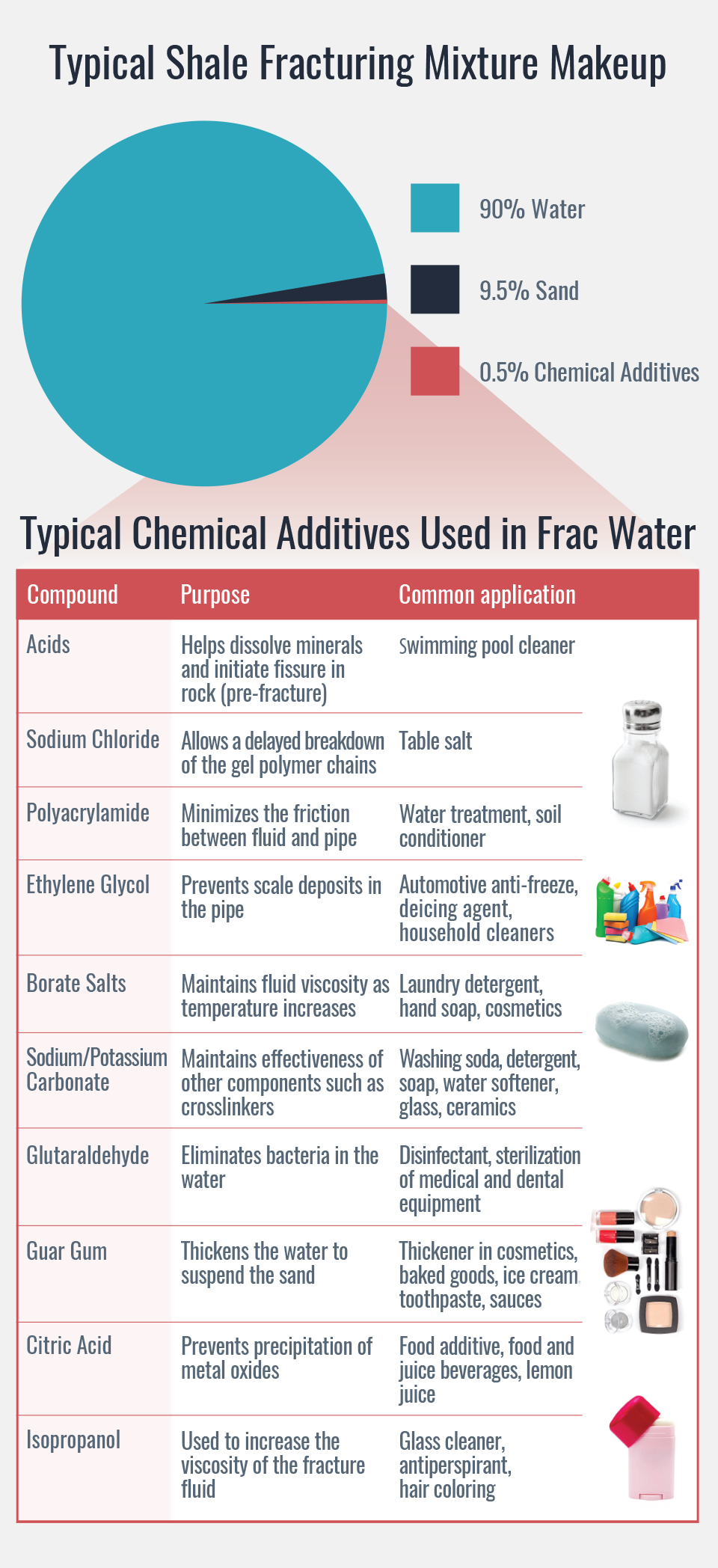

About 90.0% of the frac fluid mixture is water and 9.5% is sand. The remaining 0.5% consists of chemical additives. The additives are compounds we encounter every day in common food additives, household cleansers and automotive antifreeze.

Commonly for fracking in shales, about 90.0% of the frac fluid mixture is water and 9.5% sand. The remaining 0.5% consists of chemical additives to enhance the fracturing process. Additives are used to change the performance of the fluid throughout the fracking process to protect the reservoir from bacterial growth and the equipment from corrosion. Many of these additives are compounds that are used in other applications one encounters in daily life

Source: United States Department of Energy

Fracking additives are similar to other industrial or household chemicals that must be handled properly. For certain chemicals, safe work practices, proper site preparation and attentive handling are required to ensure that employees, the public and the environment are protected. Regulators require operators to maintain an inventory of the chemical products used downhole or stored at a wellsite, including frac chemicals. These chemicals must have Material Safety Data Sheets (MSDS), which are available for all personnel on the job site. The MSDS outlines the hazards associated with the chemical and the appropriate steps to protect the user and the environment.

Canadian provinces and territories have strict requirements for use, containment and management of chemicals. Companies are also required to post the additives used for each well on FracFocus, a public registry with broad information.